Interactive learning with gears ⚙️🤔

- Fiona Ling

- Nov 17, 2024

- 7 min read

First practical, and guess what—it’s all about gears! 🛞 OMG, what are these 🔎mysterious wheel-like things? They look so intricate and complicated. How am I supposed to figure out which one to use and when? It’s like stepping into the world of tiny mechanical puzzles!

But don’t worry—I’ve got you covered! I’ll break it down for you right here in the most fun and interactive way possible. We’ll explore what gears are, how they work, and why they’re so essential. Think of this as a mini adventure into the mechanics of motion—where science meets magic (well, almost ✨).

✦ . ⁺ . ✦ . ⁺ . ✦ . ⁺ . ✦ . ⁺

What are gears and some introduction to the definitions?

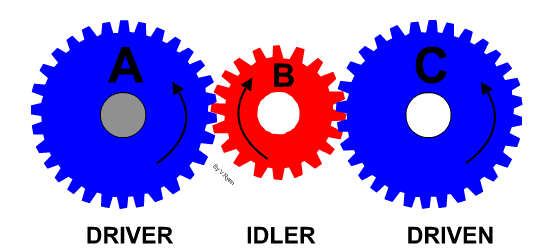

The picture at the left is a example of gear system.

A group of gears that interact with each other to change the speed, torque and rotational direction from the input (driver) to the output (driven). These changes can be mathematically modelled using the gear ratio.

An idler gear is a gear placed between the input (driver) gear and the output (driven) gear in a gear train. The idler gear does not affect the gear ratio or the speed of the output gear; its primary purpose is to transmit rotation from the input gear to the output gear so they rotate in the same direction without changing the ratio between them.

Let's have a closer look into one of the gears!

🌷Terminologies & Symbols 🌻

(PCD) Pitch Circular Diameter: Imaginary circle that passes through the contact point between two meshing gears.

(m) Gear module: The size of gear teeth.

Unit in mm.

- The larger the module number, the larger the teeth size.

(z) Number of teeth

So how these buddies team up? 🤔

In a more layman term ~

Imagine PCD is the size of your gum, and most adults have 32 teeth, divide them and you'll get the size of each teeth you need to have.

Module, m is directly propotional to the pitch circular diameter, PCD.

Module, m is inversely propotional to the number of teeth, z.

These are the introduction of the gears! Then how do we apply and arrange gears to meet our requirements?

·········⋆༺𓆩❀𓆪༻⋆·········

Here comes the main character for this topic!! Gear ratio (it is tested and used a lot here :9)

Relationship between gear ratio, output speed and torque:

Another name for gear ratio is speed ratio.

The gear ratio is the ratio of the number of teeth on the output (driven) gear to the number of teeth on the input (driving) gear. It describes how much one gear will rotate relative to the other. In a gear pair, this ratio determines the trade-off between speed and torque.

This is the most basic formula for gear ratio:

With the relationship that we learnt earlier about number of teeth, PCD and module, we are able to derived another formula:

Torque is the measurement of how much force is needed to rotate a object. For example when you are loosening a bolt with a wrench, the force that you are using is torque.

So in this case, we can see that the PCD and number of teeth has an impact on the torque that the gears will produced.

Hmmmmm..... so how do we know what size of gears do we need?

⠂⠄⠄⠂⠁⠁⠂⠄⠄⠂⠁⠁⠂⠄⠄⠂ ⠂⠄⠄⠂☆⠂⠄⠄⠂⠁⠁⠂⠄⠄⠂⠁⠁⠂⠄⠄⠂ ⠂⠄⠄⠂☆⠂⠄⠄⠂⠁⠁⠂⠄⠄⠂⠁

When the gear ratio is higher,

the driver gear is smaller, having less number of teeth and smaller teeth size.

the produced torque is higher

the produced speed is slower

(vice versa for lower gear ratio :>)

This shows that there's a trade of between the torque and speed produce.

This depends on the type of function that we are creating through the gears 💡

If a speed multiplier gear is needed,

which is to produce faster speed, we need a lower gear ratio.

The driver gear will have a bigger size than the driven gear.

For example, BICYCLE

As you can see the paddling section is connecting to the bigger gear, as such to create a faster speed.

If a torque multiplier gear is needed,

which is to produce larger torque, we need a higher gear ratio.

The driver gear will have a smaller size than the driven gear.

For example, INDUSTRY CONVEYOR BELT:

To successfully moves the heavy objects, a larger torque is needed (imagine carrying the tire one by one ourselves, quitting the job after half day...)

Hence, a gear train with higher gear ratio can help us do the work.

Designing a better hand-squeezed fan

We are given a d.i.y hand-squeezed fan that look like this:

After using a few times of this fan, I have a lot of thought to say 🤔

The handle always stuck after every push and a initial force is needed to make it work

The gears mechanism is not as smooth as I imagine. Why do we need do pull out the handle after every squeeze? Not only that, why is it so hard to make the first push.

The whether is too hot, I don't have time for this (┬┬﹏┬┬)

So I have come up with this design to improve the fan mechanism, making sure everything goes flying 🍃

The design sketch:

#ps: why drawing the gear's teeth so hard :(

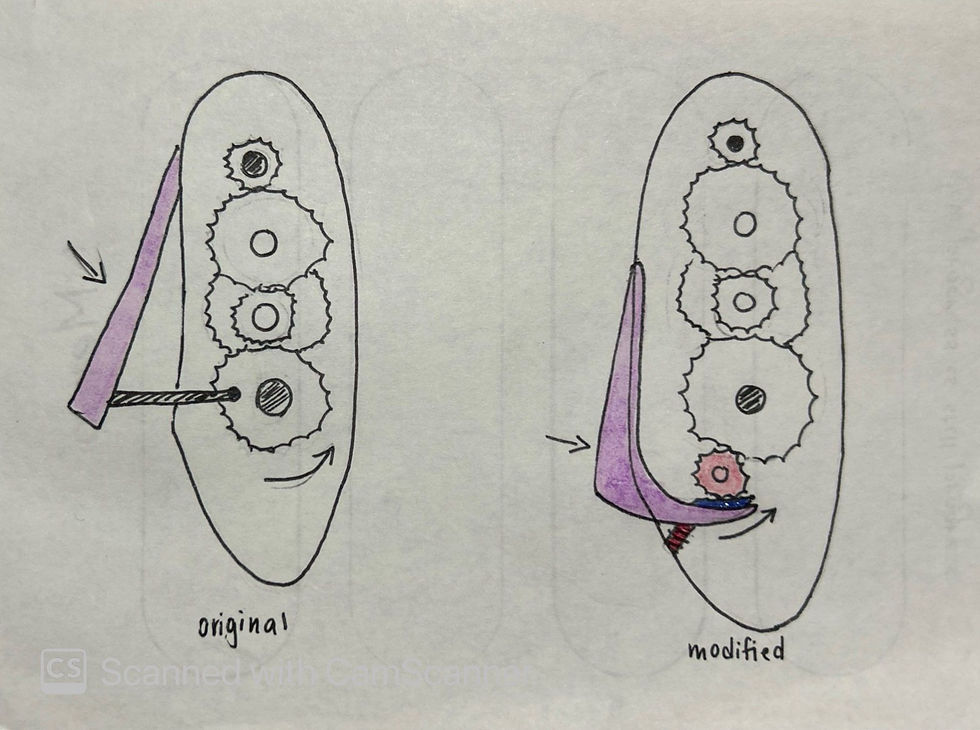

The left drawing is the original arrangement, the right side is my modified arrangement.

In the original idea, there is a lever connecting the handle and the first gear. A initial larger force is needed to move the lever so that it can rotate the gear and hence moving the whole gear train.

In the modified idea, the handle is designed in a way that it is aligning along the casing. There are some teeth on the bottom of the handle with the same module of the pink coloured gear. The purpose of the pink gear is to reduce the torque needed to move the gear train. With a smaller size of gear, less torque is required to rotate it.

There is another spring on the bottom of the case, that is attached to the handle. When the handle is pushed, the spring will be extended so that the gear can rotate. After the handle is released, the spring will pull back the handle to the original state. No more cranky handle!

Let me explain more about the change in the gear⚙️

The initial gear is the biggest gear in this gear train. That is the reason why we need more force at first to turn the gears. If we can add another gear that is smaller, less force will be required to turn the gears. However, the additional gear must be larger that the last gear which is Z6. To produce faster rotating speed of the propeller, the last gear must be smaller so that the gear ratio is lower.

"The gear arrangement of the initial idea"

The aesthetic of the fan is not a vibe 💅🏻

The handle is sticking out too much and it is a trouble to keep it in your bag. Imagine being tangled and and it's so hard to take out. With the new design, the handle is more compact and causing less trouble.

The casing of the fan is hollow and it will collect dust easily. It would be better if the casing is fully covered without holes.

With this new design, no more cranky fan, enjoy the speed of the wind and go out happily 🌻🌷🍃🌞☁️

⊹₊ ˚‧︵‿₊୨୧₊‿︵‧ ˚ ₊⊹

Activity to raise the water bottle 20cm from the floor

Here comes the hardest part for this practical. Before we went for the practical, my group had tried different combinations of gear train and we finally found the best that we can.

Here is the gear arrangement of the gears:

And this is how it looks like in real life,

#Hiii, that's Muhsin at the back

It's so hard to put them together, a prove that this is a three man job

+ a photographer.

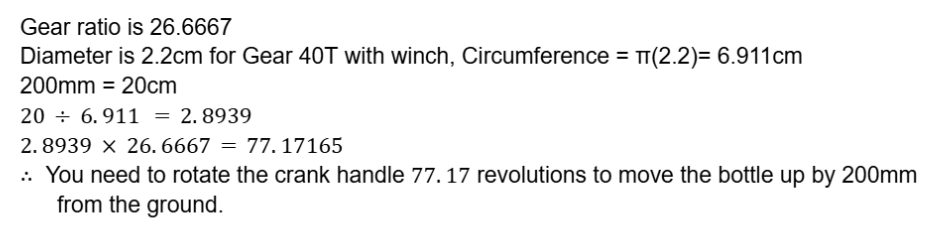

Calculations for the gear ratio:

How to find the number of revolution through formula:

We first calculated the circumference of the 40T gear. By dividing it with the the distance of the water bottle, we will get the number of revolution gear 40T needs. From the gear ratio, we will hence get the number of revolutions of the first gear.

The actual gear transmission is 50 rotations which is less than the theoretical gear transmission of 77.2 this is because as the winch rotates its diameter slowly increases as the line wraps around the winch which results in the required number of rotations for the crank handle to be lesser, as each rotation covers more distance. In the calculation, we used the average diameter of gear 40T.

Enjoy the videos of Muhsin spinning the gears :>

The video is sped up to x10 so the actually process is very very slow (I shall not take up your time here). In this case, we are required to lift up an object hence a larger torque should be produced. Unlike the hand-squeezed fan that need to produce speed, we put the bigger gear at the end.

So now you know what's the different type of arrangement is needed for different purposes.

My learning reflection in these gear activities 💖💗

From this blog that I have been talking a lot about gears, yes I am confidence in this topic and had understood it. This wasn't the case at first. When I chose Chemical Engineering as my diploma, I was not expecting to be here learning about all these mechanism as well. I was so overwhelm by all these gears turning in my face. Like I had stepped into a world that I wasn't prepared for.

The funniest part of this practical was during the test, when me and my groupmate were just drawing circles in the air to figure out the turning direction 🤣In real life, this scene looks ridiculous and made everyone laughed. The energy in the group is amazing✨. This just shows our dedication to understand this topic, everyone is on fire 🔥

I really had a great time with my groupmates throughout the activities. I am so glad that everyone is actively involved, no one was slacking off. This teamwork made the learning process fun and effective. It's amazing to see how we are so glued together by the gears.

Through this leaning, I have learnt how to appreciate gear mechanism on how it really makes our life easier. Like the bicycle and hand-squeeze fan, those are some daily objects that had given me convenience but we never talk about how gears contribute in it. Science is part of our life and quietly doing the tedious work for us.

As an engineering student the knowledge that we are gaining now will be useful when we are building our own protype next time. Who knows when we will need to design with gears. (Honestly. I would not mind if my brain have more gear so I can think faster as well). This experience has reminded me that even the smallest mechanism can make a big difference, both in our design and in the way we solve problem.

That's all for this first blog and I hope you enjoyed reading my experience. See you again in my next post!!

Sincerely by Fiona 💗

Comments